方案解决

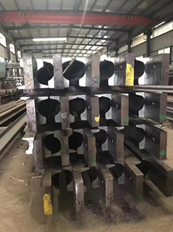

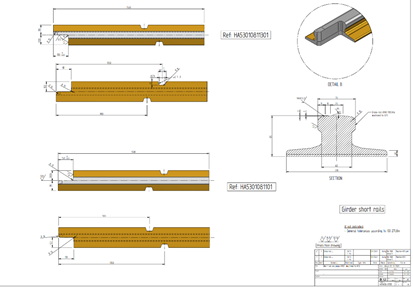

我司可根据客户要求,提供钢轨的切割设计方案,包含L型切割,直角切割。

Our company can according to customer requirements, provide rail cutting design, including L cutting, right Angle cutting.

更多产品细节 ,请联系我司业务人员。

For more details, pls contact us.

钢轨切割 Rail cutting

安装服务 Installation service

轨道折弯-Rail bending

我司可以依据用户需求,采用冷弯或者加热成型方式,以满足客户对钢轨不同弧度的要求。

We can use cold bending or heating forming according to user requirements ,in order to meet customer’s demand for different radius of rail.

- 钢轨喷涂 Rail paiting

我司可提供不同的喷涂工艺,以满足客户对不同等级防腐的要求。

Our company can provide different spraying process to meet the requirements of customers for different levels of anticorrosion.

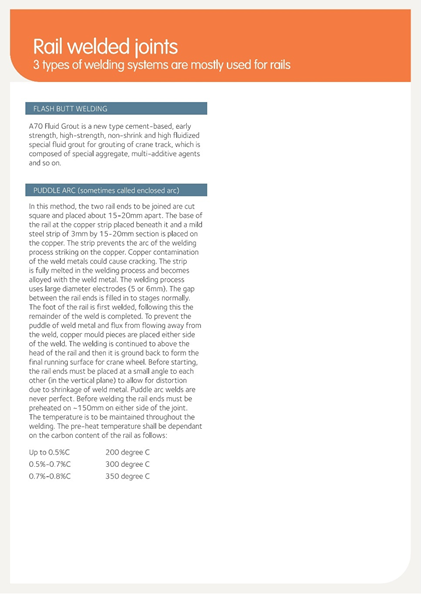

- 钢轨焊接 Rail welding

In thermit welding, a refractory mould is placed around the two square cut rail ends. The gap between the rail ends is about 15mm. The rail is preheated to a temperature dependant on the chemical composition of the rail and the precise welding process. A crucible containing a combustible powder, iron and alloying elements is placed above the mould, the powder is ignited and when it attains the correct temperatures, it melts a plug and flows into the mould. The cooling and post weld heat treatment of the rail are chosen dependant on the rail material and the application.

更多细节,请见以下文件:

For more details ,pls see below:

在热熔焊接中,一个耐火模具被放置在两个方形切割轨道的两端。轨端间距约为15mm。钢轨的预热温度取决于钢轨的化学成分和精确的焊接工艺。一个含有可燃粉末,铁和合金元素的坩埚被放置在模具上方,粉末被点燃,当它达到正确的温度时,它融化一个塞子并流入模具。钢轨的冷却和焊后热处理的选择取决于钢轨材料和应用。